Introduction

The chemical industry is facing mounting pressure to accelerate innovation, reduce costs, and meet stringent sustainability regulations. Traditional R&D approaches, heavily reliant on trial-and-error experimentation, are proving too slow and resource-intensive to keep up with these demands. Why spend months testing in the lab when you could have the answers in days with computational chemistry? This is where computational chemistry comes in. A game-changing technology that is transforming how new chemicals are designed and tested.

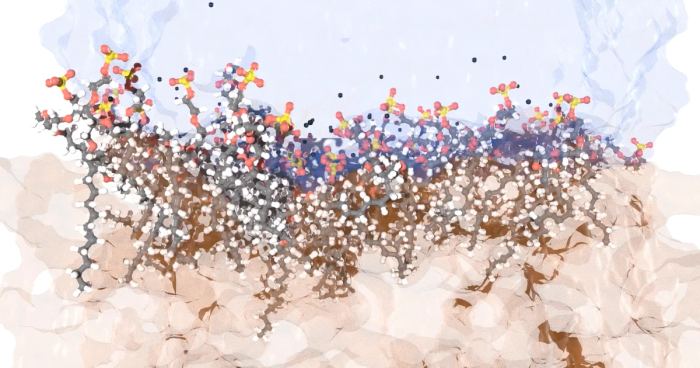

By leveraging molecular modeling, artificial intelligence (AI), and high-performance computing, computational chemistry allows researchers to characterize chemical compounds and formulations virtually before synthesizing them in the lab. This shift not only speeds up the design process but also cuts costs and environmental impact.

What is Computational Chemistry?

Computational chemistry is the use of mathematical models and computer simulations to predict molecular behavior, chemical properties, and reaction mechanisms. It allows scientists to analyze, visualize, and optimize molecular interactions without physical experimentation, reducing reliance on expensive and time-consuming lab tests.

There are several key techniques used in computational chemistry:

- Molecular Dynamics – Simulates the behavior of molecules under various conditions for thousands up to millions of atoms.

- Quantum Chemistry – Computes electronic properties and reactivity for a few hundreds of atoms.

- AI / Machine Learning – Identifies patterns in molecular data to accelerate molecular discovery.

- High-Throughput Screening – Automatically evaluates thousands of chemical candidates.

These techniques enable companies to test molecules in silico before selecting the best candidates for physical testing, significantly reducing R&D cycles from years to months.

Why is Computational Chemistry a game-changer for R&D?

1. Accelerates innovation with digital technologies

The integration of digital technologies, such as molecular modeling and AI, is transforming chemical R&D. Computational chemistry enables researchers to simulate and predict molecular behavior, significantly reducing trial-and-error experimentation.

For example, BASF, Covestro and L’Oréal are using computational chemistry to design new and better-performing products. Companies that embrace these digitalization strategies gain a competitive edge by developing novel formulations faster and at lower costs.

2. Reduces R&D costs and time-to-market

By replacing costly lab experiments with computer simulations, companies can reduce R&D costs by up to 90%. This is particularly critical in industries where new regulations demand reformulation of existing products, such as the EU Green Deal’s push toward sustainable chemicals.

Nextmol’s platform, for instance, accelerates chemical R&D by 5x, enabling companies to test formulations virtually before selecting the most promising ones for physical validation.

3. Enables sustainable innovation

Sustainability is no longer an option, it’s a necessity. Environmental concerns and regulatory pressures are pushing the chemical industry toward greener practices. Computational chemistry plays a key role in green chemistry initiatives, helping companies:

- Develop bio-based chemicals that replace petrochemical-based ingredients.

- Develop catalysts that enable green chemistry reactions and green solvents that are less harmful to the environment. Predict biodegradability based on existing data.

4. Supports compliance with industry regulations

New regulations, such as Safe and Sustainable by Design (SSbD), require companies to evaluate safety and environmental impact from the earliest stages of development. Computational chemistry provides predictive tools that help companies to assess regulatory compliance upfront, avoiding costly late-stage redesigns.

5. Enhances collaboration and digitalization

One of the biggest shifts in chemical R&D is the move toward open innovation and collaboration. Until recently, companies closely guarded their R&D knowledge, but as innovation cycles accelerate and sustainability becomes a shared challenge, collaboration across the value chain is key.

Computational chemistry integrates seamlessly into digital R&D ecosystems, allowing teams to centralize data, automate workflows, and streamline decision-making. This is particularly beneficial for companies developing next-generation biopolymers, sustainable surfactants, and functional materials.

6. Unlocks the potential of petrochemical alternatives & biotechnology

While petrochemicals continue to play a key role in industrial chemistry, computational chemistry is enabling the transition toward sustainable, bio-based alternatives. Companies are investing in computational approaches to design:

- Biopolymers for sustainable packaging

- Bio-based surfactants for personal care and detergents

- Enzyme-driven chemical processes for greener synthesis

The Future of Chemical R&D is Digital

Computational chemistry is no longer a niche technology — it is becoming a mainstream tool for innovation in the specialty chemicals industry. From personal care ingredients and detergents to coatings and packaging, companies that embrace digital R&D will gain a competitive advantage in speed, cost-efficiency, and sustainability.

At Nextmol, we provide a powerful software platform that combines molecular modeling, AI, and high-performance computing to accelerate chemical innovation in polymers and surfactants. Our platform enables R&D teams to design and characterize molecules and formulations virtually before synthesis, cutting development time by 5x and costs by 9x.

Want to see how computational chemistry can transform your R&D? We’d love to hear about your challenges and help you find a solution.