Modern engine lubricants are a complex blend of a base oil and a package of dissolved additive molecules (5-20%) that impart new properties or improve existing ones. This additive technology has been indispensable for lubrication since it was born in the early petroleum age.

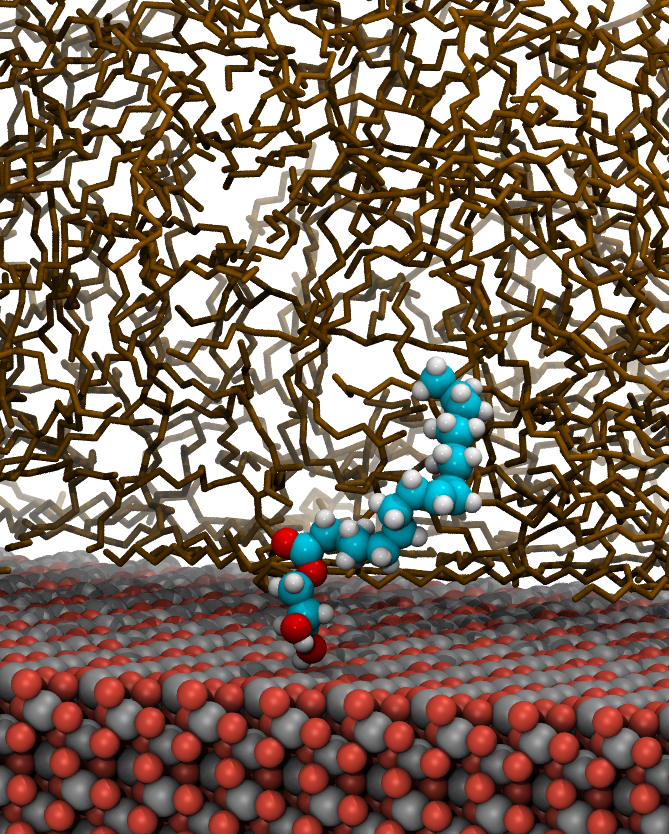

Considering their function, lubricant additives can be classified into detergents, dispersants, viscosity-modifiers, anti-wears, corrosion inhibitors or friction modifiers. The performance of friction modifiers and anti-wears depends on their ability to reach the surface and form a protective film, while competing with contaminants and other additives for adsorption onto the surface. Therefore, combining additives with an adequate surface affinity balance is specially important when formulating lubricants.

Even though lubrication engineering is a mature technology, these mixtures are still being developed mostly by trial-and-error experiments, varying additive concentration in the base oil, surface coatings, etc. and measuring friction and wear. A common blind spot suffered by this kind of experiments is the surface concentration of each additive. The relation between the bulk concentration and the surface concentration is also known as the adsorption isotherm, which has to be measured in additional experiments. Efficiently assessing the affinity of additives to different surfaces would provide valuable information for the rational design of lubricant formulations and additive molecules.

Nextmol has used state-of-the-art methodologies in molecular modeling to predict this adsorption isotherm in silico. The approach is based on a well-established Molecular Thermodynamic Theory model that takes as input some parameters calculated from Molecular Dynamics simulations. The method has been showcased using organic friction modifiers (OFMs) in a joint project with Repsol Technology Lab. Moreover, this novel approach, which combines thermodynamic theory and molecular dynamics, can be applied to study surfactant adsorption in different applications beyond additives in lubricant formulations, such as anti-agglomerants, corrosion inhibitors, anti-foaming agents, emulsifiers, etc.

Read our paper and case study or contact us for more information. You may also be interested in our blog article Lubricant additives: Friction modifiers.