Challenges in Polymer Research and Development

Polymers are essential in the chemical industry, found in materials, adhesives, additives, packaging, and more. Their diversity and complexity make them highly versatile, suitable for a wide range of applications. However, these same attributes make their study challenging. Properties like tacticity, cross-linking, entanglement, and molecular weight are often difficult to control experimentally, complicating the research and development (R&D) of new polymers. Trial and error along with repeating synthesis and characterization processes can hinder progress, while establishing structure-activity relationships through characterization studies proves time-consuming and costly.

How Computational Modeling Transforms Polymer Innovation

With the rise of computational capabilities in recent years, the industry has increasingly turned to computational modeling for R&D processes. Computational polymer design offers several advantages over traditional experimental studies, including faster research, reduced use of synthesis reagents, and minimized risks. All-atom simulations further enable an in-depth analysis of the interactions between system components, helping to uncover the microscopic origins of macroscopic properties.

Despite its benefits, computational polymer design presents its own challenges. Polymers can consist of thousands or even millions of monomers, forming chains with varied connections and repetitive units. Additionally, their sequences often contain an element of randomness, adding further complexity to their digital construction.

Overcoming Challenges in Computational Polymer Design

For many chemical industry companies without dedicated computational chemistry teams, these challenges hinder the adoption of computational methods, leaving those who overcome them with a significant competitive edge. This is where NEXTMOL Lab steps in. At NEXTMOL Lab, we focus on providing an intuitive, specialized experience for characterizing polymers and surfactants. Our platform allows polymer scientists to extrapolate their experimental expertise into a computational framework seamlessly. This is translated into an important simplification of design processes of complex polymeric systems as high molecular weight polymers, several chains of copolymers presenting a distribution of monomeric ratios, dendrimeric polymers or new biopolymers that have not been extensively studied before. For example, building a polymer in our NEXTMOL Builder is divided into six simple steps, each progressively adding complexity until a realistic system with experimental-like properties is achieved.

Using NEXTMOL Builder, constructing the copolymer poly(ethylene-vinyl acetate) (PEVA) is straightforward and efficient:

Building a PEVA copolymer with Nextmol Builder

1. Select the monomers forming the polymer.

2. Create as many monomer sequences as desired, either predefined or generated randomly based on a ratio.

3. Define the number of sequences forming each type of chain.

4. Specify the number of chains in the polymer and adjust the simulation cell size by density or dimension specifications.

5. Select simulation conditions to achieve a more realistic structure.

6. Assign a system name and review its data.

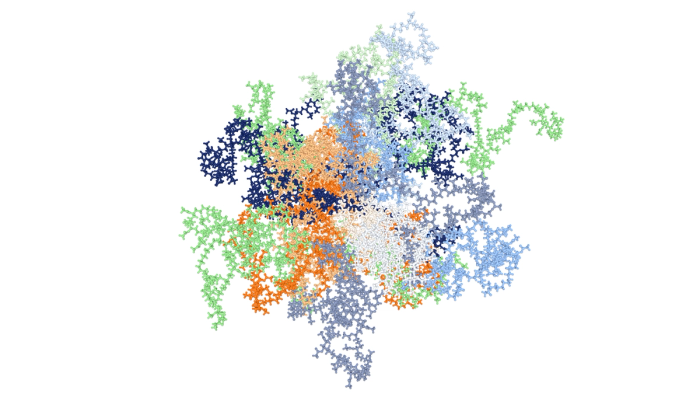

Such procedure is currently used by the R&D teams of several companies from the chemical industry to design new polymers. This process was applied to create a PEVA polymer shown in the video above with 20 chains of varying ethylene and vinyl acetate proportions: 10 chains with a 1:1 ratio, 8 chains with 1:2 and 2:1 ratios, and 2 chains with 3:7 and 7:3 ratios. The resulting model was well-entangled, providing a homogeneous system which is representative of the experimental state of the polymer.

Endless Possibilities for Specialty Polymers and Bio-based Materials

Our capabilities extend far beyond this example. You can employ various monomers, segments, and chains, customize simulation conditions, and explore different polymer types - including dendrimer polymers, which will soon be available. NEXTMOL Modeling seamlessly imports these structures for computational experiments, enabling studies on properties like the glass transition temperature, radius of gyration as well as interactions between additives and surfaces.

Ready to accelerate your polymer R&D?

If you’re interested in leveraging polymer simulations to accelerate your team’s R&D, contact us to request a demo.